Work Light Buyer's Guide - Mini Digger Lighting System

Lazer Work Light Solutions Overview:

At Lazer we are proud that our Utility Series of work light solutions are trusted across the world in key industrial sectors such as construction, agriculture, mining, and forestry. As a UK brand with all our design, engineering, and manufacturing done in-house, our lights are built to the highest standards. The result is solutions that not only deliver incredible lighting performance and durability, but improve safety, visibility, and efficiency in critical scenarios.

By working closely with operators and understanding their day-to-day challenges, we've developed high-performance work lights that are tailored to real-world demands. Our Utility Series offers a robust range of work lights, available in 25W, 45W, 50W, 80W & 170W variants. Models are also available with additional functions such as variable brightness settings, red tail-light, and beacon/strobes - ensuring there’s a solution for virtually every industrial application.

However, with a wide range of choice and features, comes one key question we hear time and again...

What Lights Would You Reccomend For My Machine?

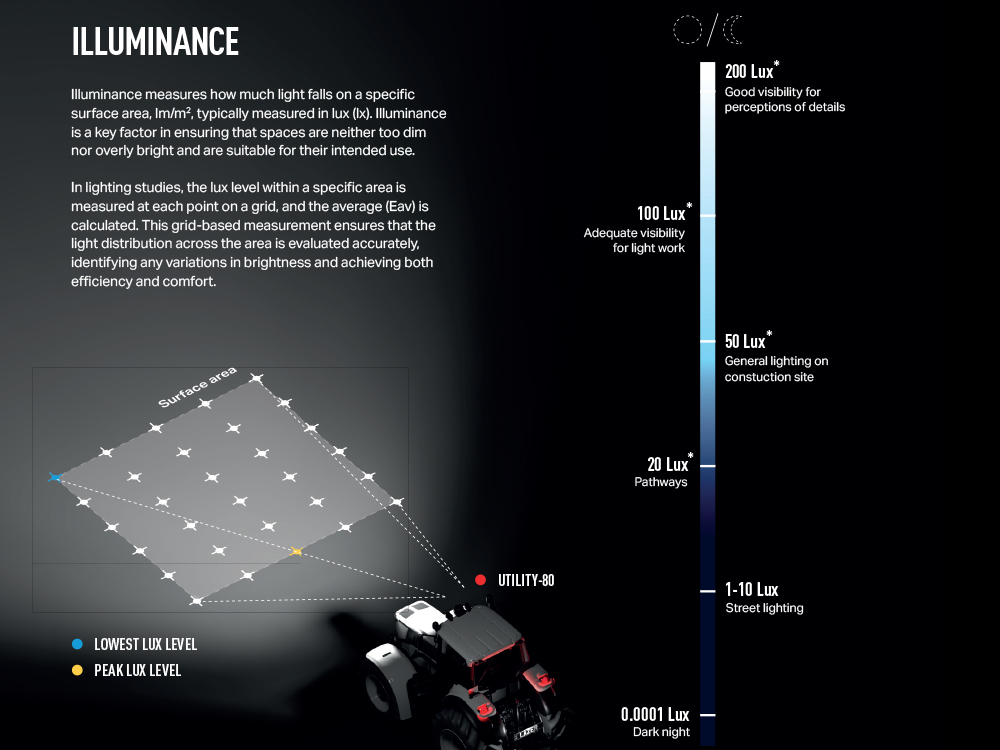

This blog aims to help answer that question. Alongside the development of new work light solutions, we’ve been using advanced simulation tools to analyse the performance of different lighting systems / set-ups. These simulations allow us to accurately assess lux levels, diffusion, and light distribution across various multiple lamp configurations. The results act as a practical guide for operators - helping them choose the ideal work light systems and set-ups to ensure the right illumination for maximum safety, productivity, and efficiency.

From this research we have developed the following case study to act as a buyer's guide for operators. The case study / guide below advises on the optimal lighting set up for mini diggers. For our excavator & tractor lighting system guides - please see the following links:

Work Light Buyers Guide - Excavator Lighting System

Work Light Buyers Guide - Tractor Lighting System

Lighting System / Set Up for a Mini Digger

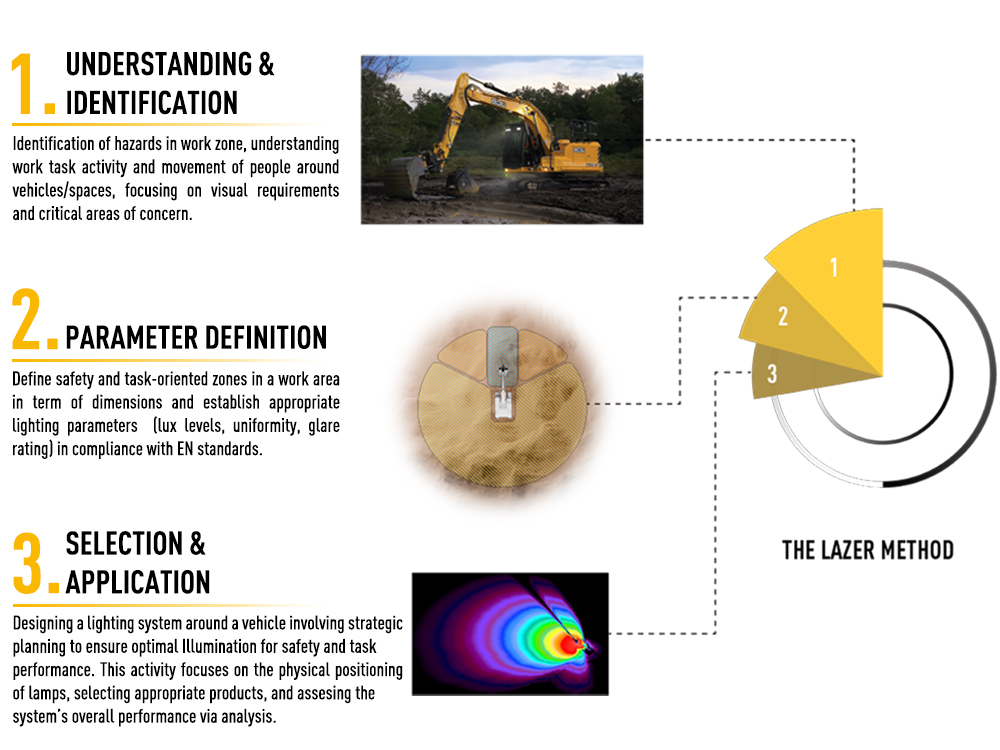

The Lazer Method: 3-Phase Process: To develop our reccomended lighting set ups and understand what combination of lights would achieve the best results, we work from a 3-Phase Process. The first step is to understand the challenges and identify the hazards that operators face. Then we can develop the lighting parameters, which involves understanding the optimal distribution of light in the areas surrounding the machine, to best meet the operators needs and mitigate hazards. The final step is utilising our innovative software to simmulate different lighting systems outputs, to find the set up that achieves this light distribution.

Zoning & Illuminance - Lighting Parameters:

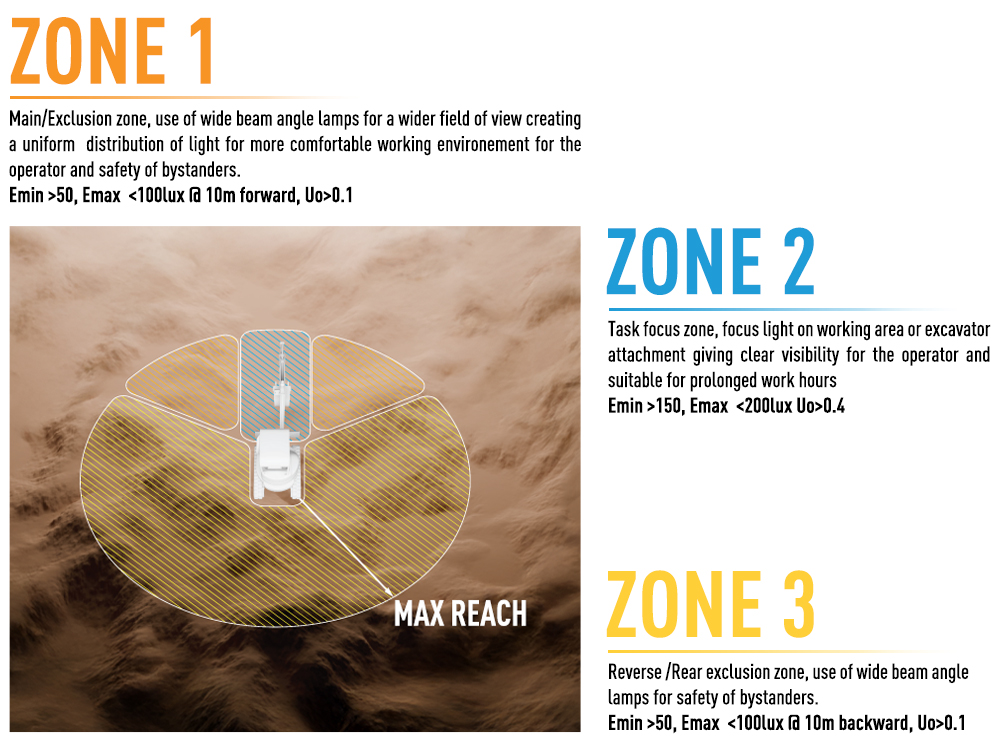

Lighting zoning involves dividing a space into distinct areas, each with specific lighting requirements based on the application, vehicle type, and operating environment. This environment is influenced by both known and potentially unknown variables. Employing this approach enhances safety, functionality, and efficiency.

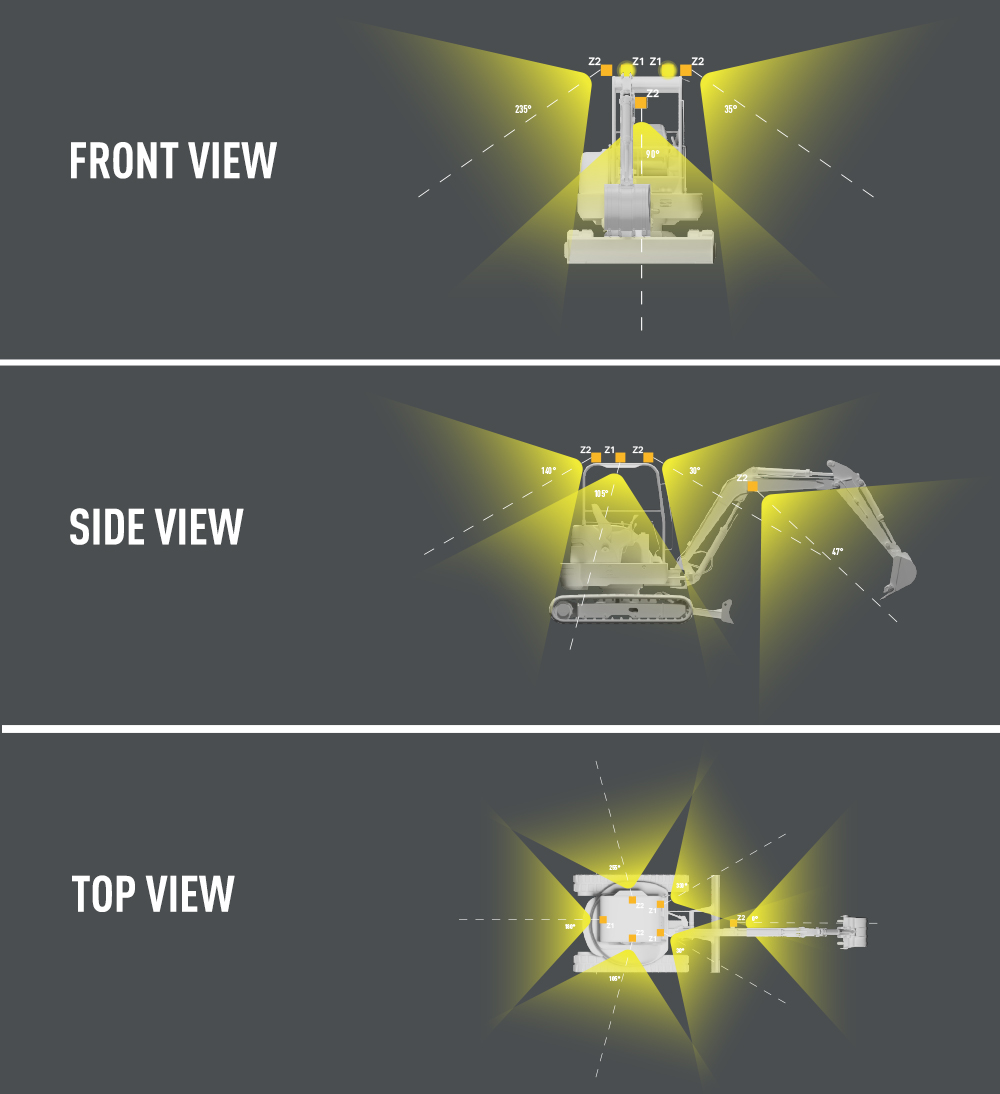

At Lazer, we leverage our expertise and advanced lighting analysis tools to work within the defined lighting zones. This enables us to recommend the ideal lamp selection, vehicle positioning, tilt angles, and beam configurations, ensuring optimal and performance. When deciding which zones to illuminate and to what extent, the operator should consider both the areas where tasks will be performed and those required for the safe movement of pedestrians or other workers. For mini diggers we have indetified the following 3 key zones:

Within each zone we then calculate the optiminal illuminance for maxiumum workability:

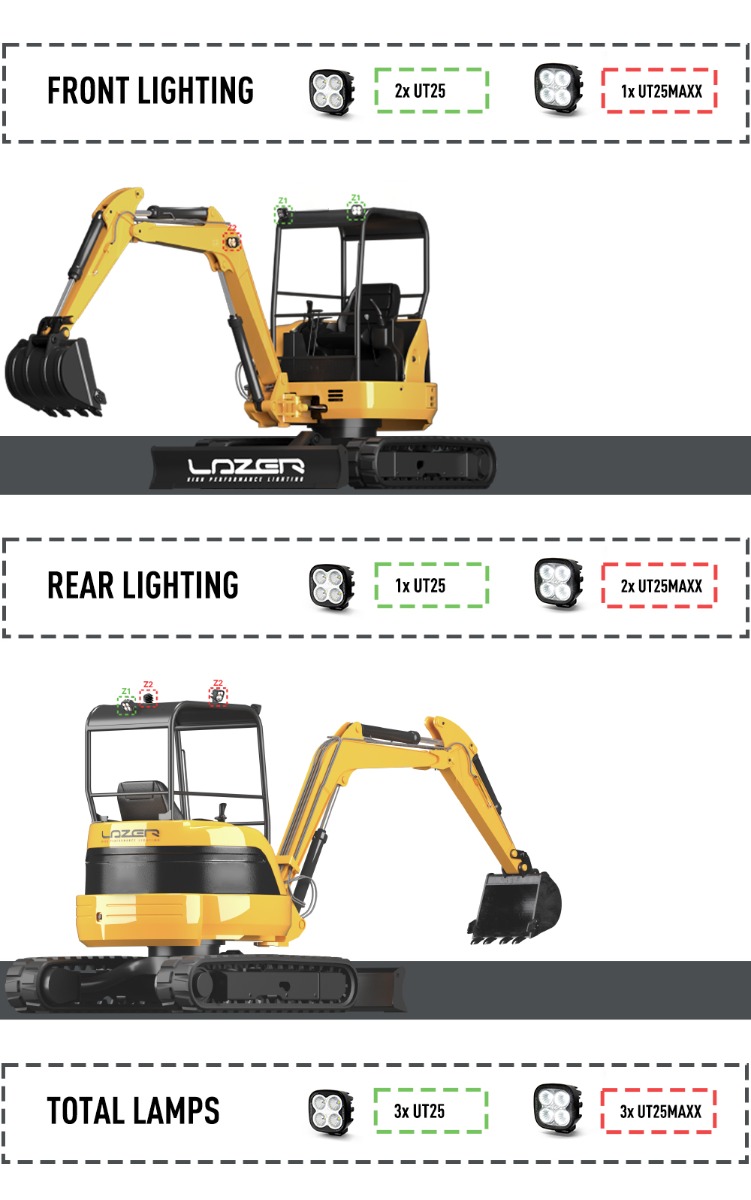

Mini Digger Front & Rear Lighting Setup:

Recognising the European standard: EN12464-2, which defines minimum safe illumination of between 20lux-200lux for outdoor excavator work, we have carefully designed the following lighting setup, which is based on achieving the best spread of light taking into account the key zoning parameters and the optimal illuminance within them. Ensuring the side and rear of the machine have clear visability is also Essential for maintaining a safe working area, our rear set up follows HSE HSG38 guidelines - which define the range of illuminance around the vehicle between 50lux-100lux.

Productivity, worker safety and visibility are enhanced through our products carefully engineered 5000K colour temperature, with a high CRI (>80), and near perfect homogeneity (reducing strain on the eyes and mimicking natural daylist as close as possible).

Lighting System Performance: False Colour Rendering

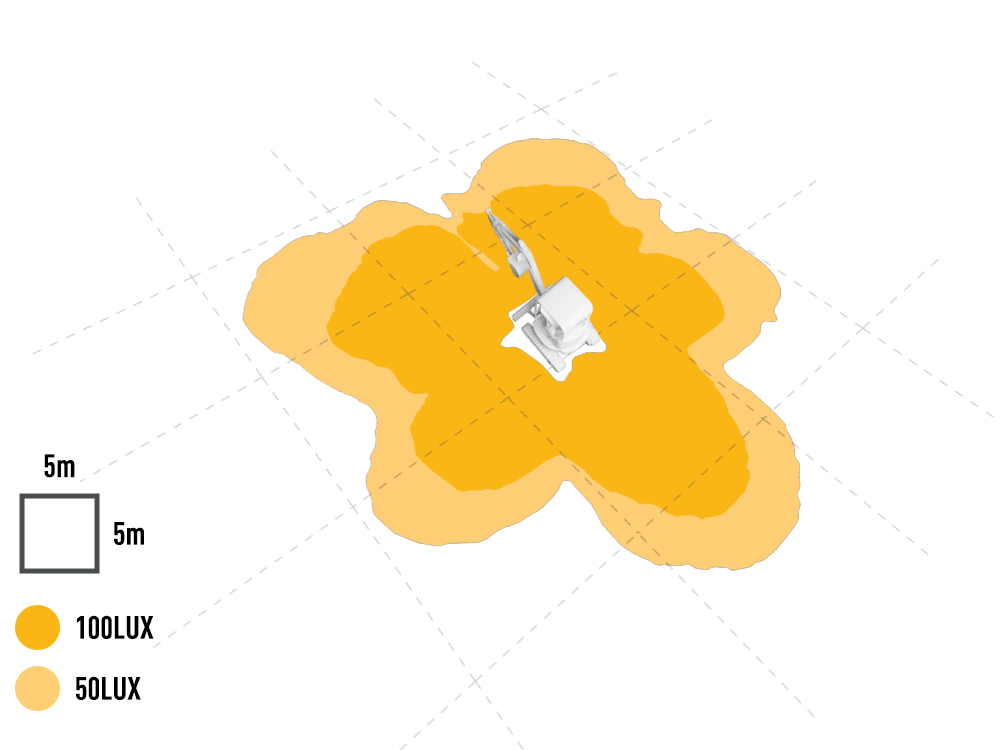

Now we have the set up established, we can begin to look at the lighting performance and output. Below is the false color rendering simulation around the mini digger, showing the distribution of light of the lighting system. The darker areas near the machine represent higher lux / light levels for tasks that require better visability and more precision , while the colour gradually lightens towards the bucket’s maximum reach, while still ensuring sufficient lux levels in the surrounding area of the excavator for operator awareness and safety.

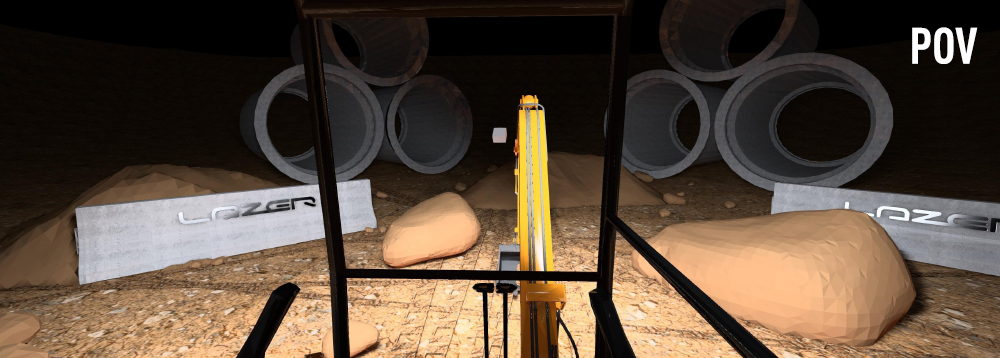

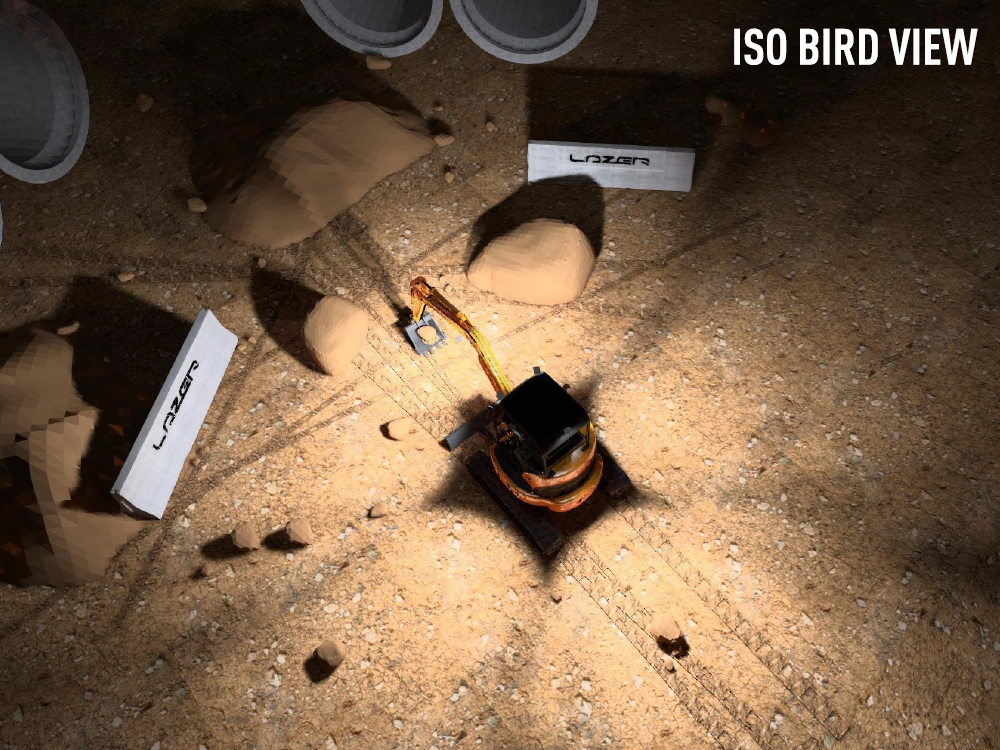

Lighting System Performance: Visual Simulations

The following simulations visualise the exact light output achieved by the case study set up, demonstrating the combination of front and rear lighting and the distribution of light in the key zones in front off and around the excavator.

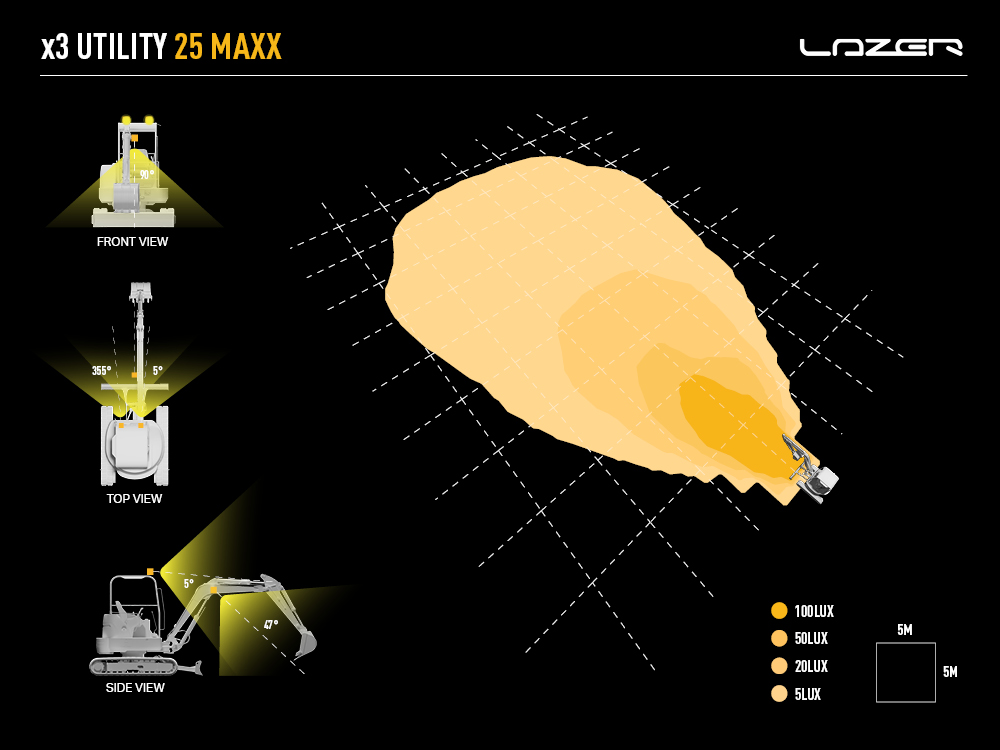

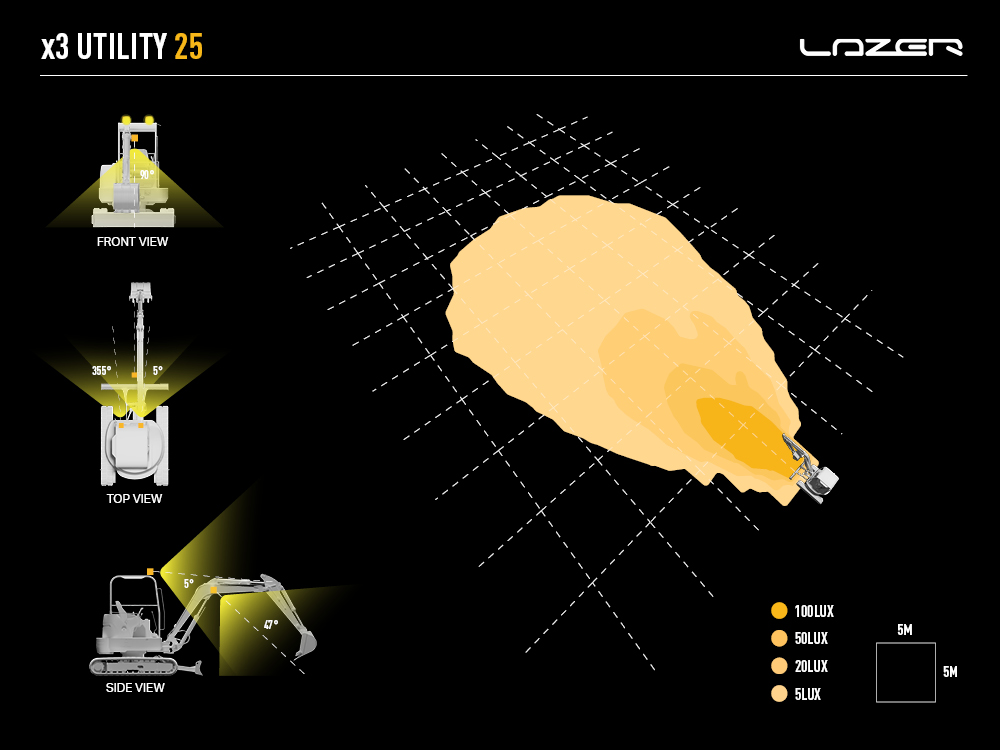

In summary, from the simulation and case study results - we can see this set up is achieving excellent levels of lighting (>100 Lx) in a wide area around the mini digger, with an otpimal level of light uniformity across all required zones. The light output is crucal but we can also see the strategic positioning of theese lamps is also key to to optimise coverage and uniformity for the operator. This result is achieved using 7 lamps in total, comprising x4 Utility-25 MAXX and ×3 Utility-25 lamps.

For more information on these products, and to see the lighting performance of alternative front lighting set ups suitable for a mini digger - please see the sections below. For any further questions - please dont hesitate to get in touch via our social media or contact us directly: +44 (0)1992 677374 / sales@lazerlamps.com

Product Details

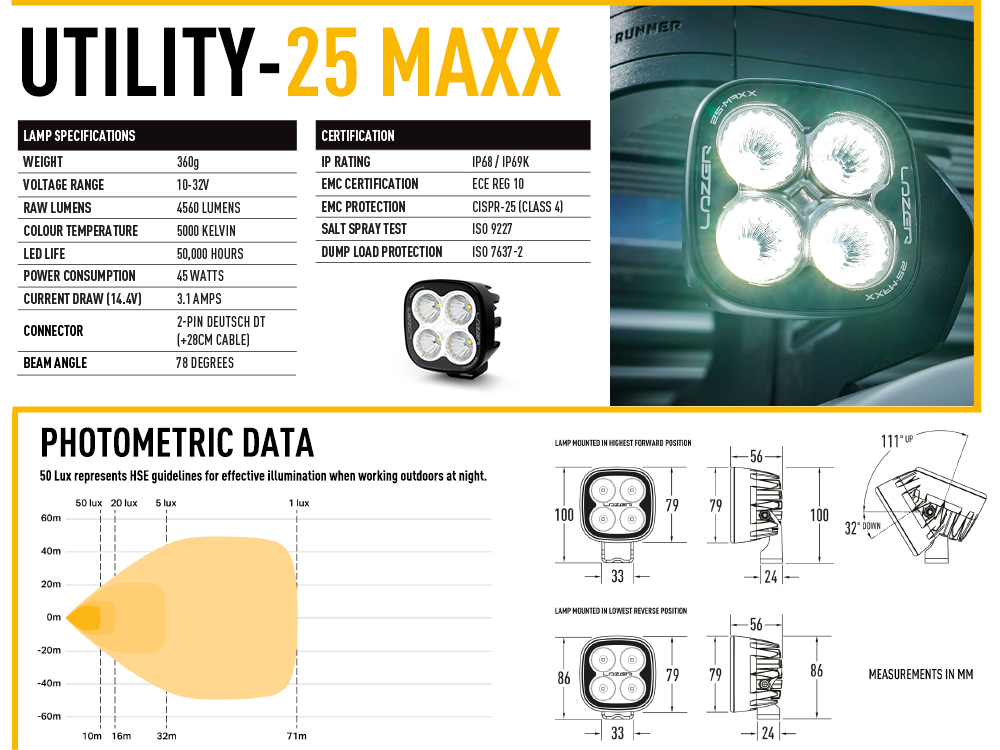

- ECE (Reg 10) approved Work Light

- CAE optimised 'Matrix' cooling system

- Advanced optical design delivers superior lighting performance

- Electronic thermal management

- Certified IP67/IP69K watertight

- Automotive grade corrosion resistance (ISO 9927 / BS EN 60068)

- 5,000 kelvin light temperature for maximum definition

- EMC protected - CISPR 25: 2008 (Class 4) certified

- Vibration Certified (BS EN 60068) : 10Hz - 2000Hz, 1 oct/min, 10gn

- Over voltage protected

- Reverse polarity protected

- Male and female 2-pin Deutsch connectors included

- 5 Year warranty*

- Made in Britain

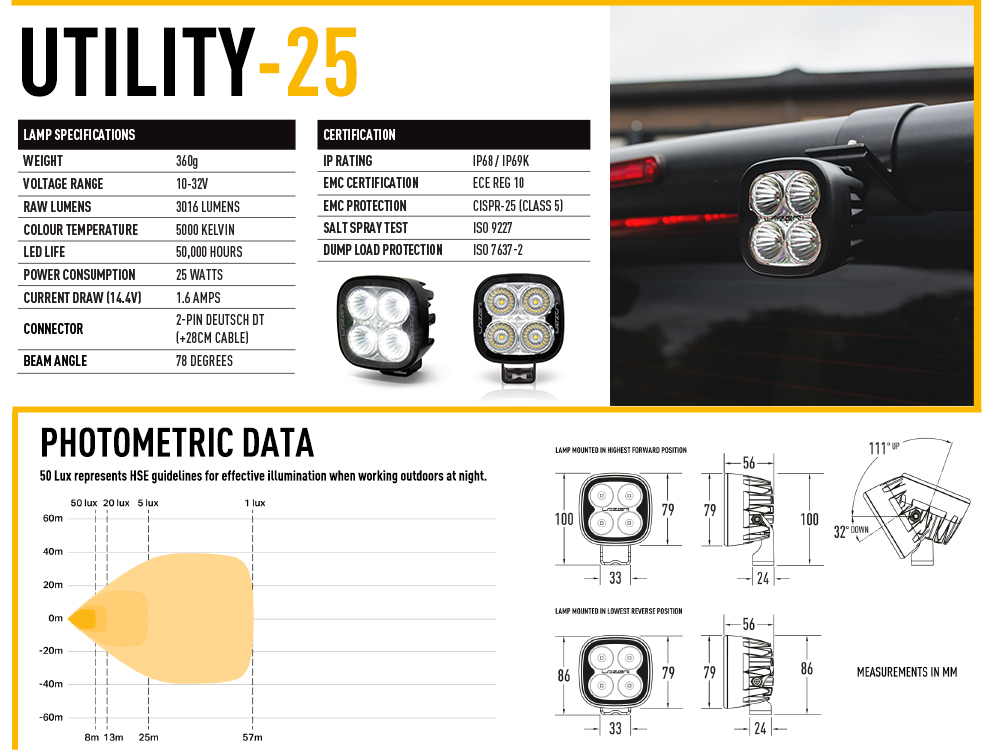

- UNECE approved Work Light (Reg 10)

- High density, premium ‘bin’ LEDs

- Advanced optical design delivers superior lighting performance

- CAE optimised 'Matrix' cooling system offers improved thermal dynamics

- Electronic thermal management system optimises light output to preserve longevity of the LEDs

- Anodised pre-treatment and automotive grade powder top-coat for ultimate corrosion and chemical protection

- EMC protected - CISPR 25: 2008 (Class 5)

- Over voltage protected

- Reverse polarity protected

- ‘Unbreakable’ polycarbonate lens with hardcoat lacquer

- IP69 watertight

- 5-year warranty*

- Supplied with pre-wired male/female 2-pin Deutsch connectors

- Designed and manufactured in UK

Other Recommended Work Light Set Ups for Mini Diggers:

To learn more about our products, explore partnerships or for any further information please get in touch with us via the details below:

+44 (0)1992 677374

sales@lazerlamps.com

To follow our Lazer's journey through social media channels:

Instagram - https://www.instagram.com/lazerlamps/

Facebook - https://www.facebook.com/Lazerlamps/

TikTok - https://www.tiktok.com/@lazerlamps

YouTube - https://www.youtube.com/user/Lazerlamps

Made in the UK

Made in the UK