Designed, Engineered & Manufactured in the UK

NOT ALL LIGHTS ARE MADE THE SAME.

At Lazer Lamps, we’ve always been incredibly proud to be a British manufacturer, and that all our products are designed, engineered and manufactured in-house in the UK. But “Made in the UK” isn’t just a statement of origin, it’s a reflection of our philosophy as a brand and how we approach every step of our product development and manufacturing process.

In the video below, our Owner and Managing Director, Ben Russell-Smith, walks you through our state-of-the-art headquarters in Harlow, Essex, whilst discussing the thinking behind our production development, our innovative manufacturing processes, and how we’re continuously improving to deliver the best lighting systems on the market.

Manufacturing Expertise & In-House Processes

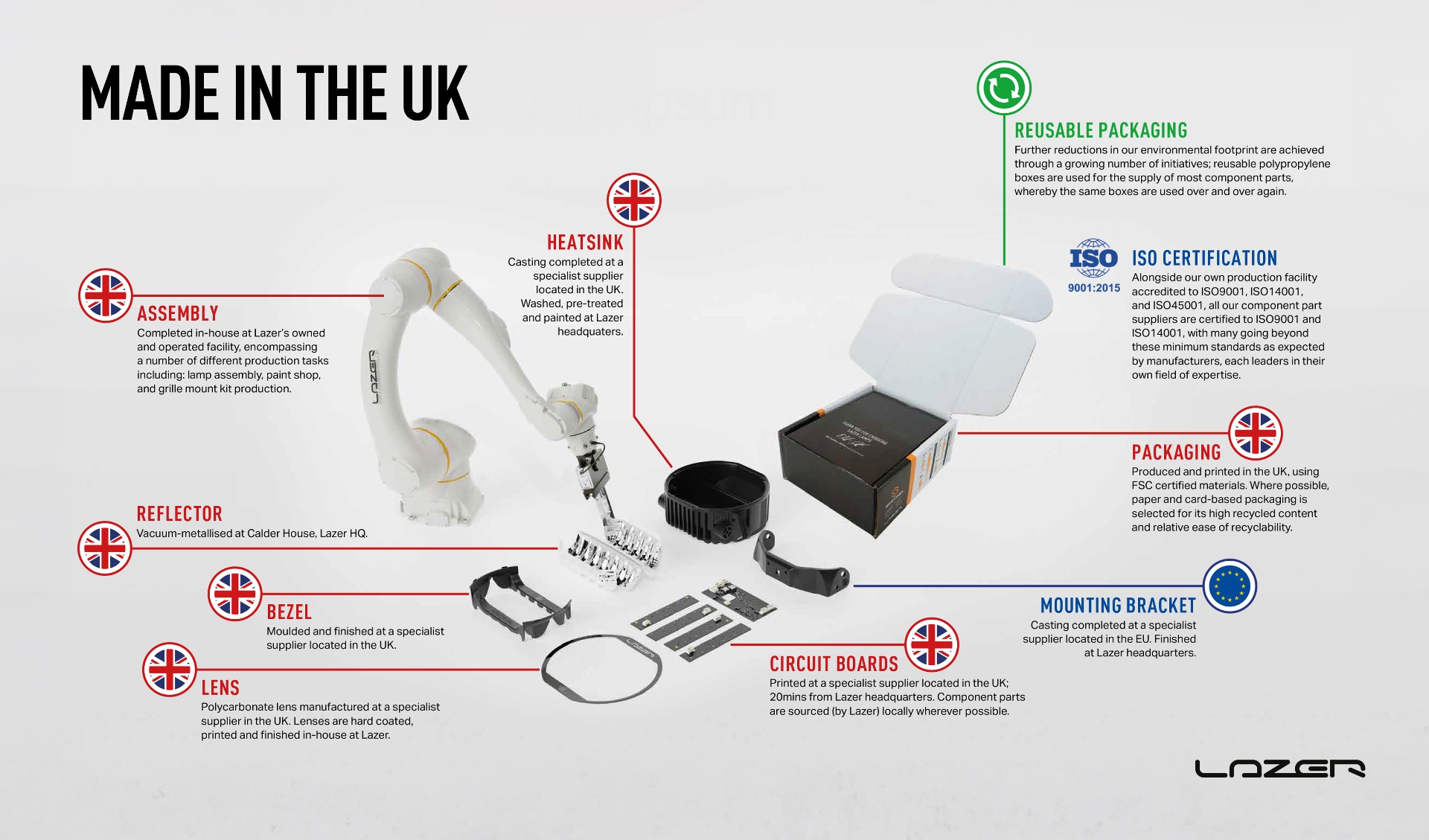

A core and fundamental part of our business strategy is to continuously bring more downstream manufacturing processes in-house. Why? Because we believe that the only way to maintain total visibility and control over product quality is to manage as much of the process ourselves as possible. By owning every step, from initial design concept through to final product assembly, we ensure the highest standards in both design and build quality, while enabling the rapid adoption of the latest technological advancements.

Recent examples of this include:

- Our new state-of-the-art powder coating facility, which features a five-stage wash and paint spraying process. With anodised pre-treatment, adhesion preparation, and automated painting, we can achieve an automotive grade powder top-coat for ultimate corrosion and chemical protection, increasing the durability of our lighting solutions dramatically.

- Our investment in addative manufacturing and 3D Printing, with higher capacity and new technology enabling us to achieve finer design details such as grain pattern and texture. We now produce 200,000 parts annually and at market leading standards of quality.

- The In-house vacuum metalizing of our reflectors ensures the production of reflectors with the highest levels of reflectivity available on the market. These ultra-reflective optics deliver the optimised beam patterns that make our lights so effective. Furthermore they contribute to the thermal management and overall efficiency of the lamps as a whole, ensuring the LED is not overworked.

- To produce our ‘Unbreakable’ Polycarbonate lenses - we now have our own hard coating line for injection moulding, supported by a brand new clean room to minimise contamination risk, alongside a pad printing machine to brand the finished lenses.

- Climate controlled storage facilities for all circuit boards to ensure longevity and efficiency, and ESD reliability.

- Our testing facilities allow us to put all our lights through a rigorous testing process, including: Vibration, Salt Spray, Environmental, and Endurance testing.

Our commitment to quality is symbolised by the fact our facilities are accredited to ISO9001, ISO14001 and ISO45001 standards. These ISO certifications provide real reassurances to customers of the standards we employ. However, the real difference comes from our people. Our Engineering, New Product Introduction (NPI) specialists and Manufacturing teams work closely together, constantly seeking ways to improve quality and workflow. This continuous improvement helps us deliver products that perform better and last longer.

Trusted UK & EU-Based Supply Partners

We are proud to source parts locally whenever possible, partnering with UK-based suppliers who share our commitment to quality. Where it’s not appropriate or possible for us to manage production of parts ourselves, the next best thing is local supply partners, each leader in their respective product areas. Their proven expertise and consistent performance ensure that every component meets our exacting requirements.

The physical proximity of these partners enables a level of agility, communication, and technical collaboration that would be far more difficult to achieve with remote or offshore suppliers. It also supports shorter lead times, greater responsiveness, and more sustainable logistics. By keeping our supply chain close and aligned with our values, we strengthen product quality, reduce risk, and support local industry, all while delivering better outcomes for our customers.

Sustainability at Our Core

Our commitment to sustainability isn’t just a checkbox, it’s built into every decision we make. We’ve already made significant strides toward reducing our environmental impact:

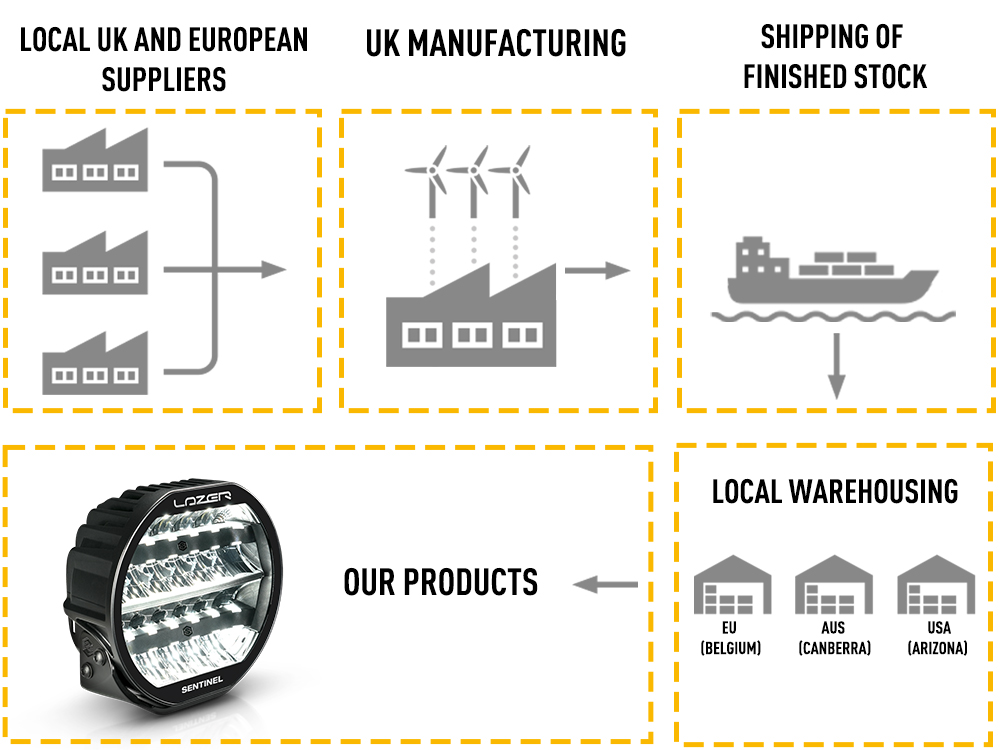

- LOCAL UK AND EUROPEAN SUPPLIERS: Prioritised in the supply chain and during sourcing activities to reduce our upstream transport emissions, and to ensure they follow EU environmental and human rights standards and guidelines.

- UK MANUFACTURING: In line with UKAS accredited, globally recognised environmental standards, including ISO14001

- SHIPPING OF FINISHED STOCK: We track all our transport emissions for our downstream distribution. In 2024, only 7% of our sales were shipped by air and we’re always looking at ways to reduce this number. For our internal distribution to our subsidiaries and warehouses. UK–BEL: 98% of our stock goes by HGV. UK–AUS: 80% of our stock goes by cargo ship. UK–US: 78% of our stock goes by cargo ship. The rest of the stock (4.5% of all internal distribution) goes by air. And we also sign up to DHL Go Green Plus scheme, which uses and invests in Sustainable Aviation Fuel for our air shipments.

- LOCAL WAREHOUSING: In each major market, for effective and low-carbon distribution: EU (BELGIUM) / AUSTRALIA (CANBERRA) USA (ARIZONA)

- OUR PRODUCTS: Always have maximum efficiency and outstanding optical design, so that you can be sure for every watt of power consumed, you are getting maximum visibility on the road.

Market-Leading Lights, Built the Right Way

At Lazer Lamps, UK manufacturing is more than a point of pride, it’s the foundation of everything we do. By keeping design, engineering, and manufacturing in-house, we’re able to deliver lights that consistently outperform any other products available in the market, in terms of build quality, technology and performance. Our ongoing investments in cutting edge technology, downstream production processes, and in people, ensure we stay at the forefront of innovation, while our commitment to sustainability and continuous improvement reflects a broader responsibility to both our customers and our community.

Every decision we make is driven by the goal to deliver our customers across all the sectors we supply, with the highest-performing lights on the market, so when we say not all lights are built the same, we mean it. The meticulous level of detail, the time, care, and engineering expertise that goes into every Lazer product ensures market-leading performance and reliability - with no compromises. That’s the Lazer difference, and we're incredibly proud of it.

To learn more about our products, explore partnerships or for any further information please get in touch with us via the details below:

+44 (0)1992 677374

sales@lazerlamps.com

To follow our Lazer's journey through social media channels:

Instagram - https://www.instagram.com/lazerlamps/

Facebook - https://www.facebook.com/Lazerlamps/

TikTok - https://www.tiktok.com/@lazerlamps

YouTube - https://www.youtube.com/user/Lazerlamps

Fabriqué au Royaume-Uni

Fabriqué au Royaume-Uni